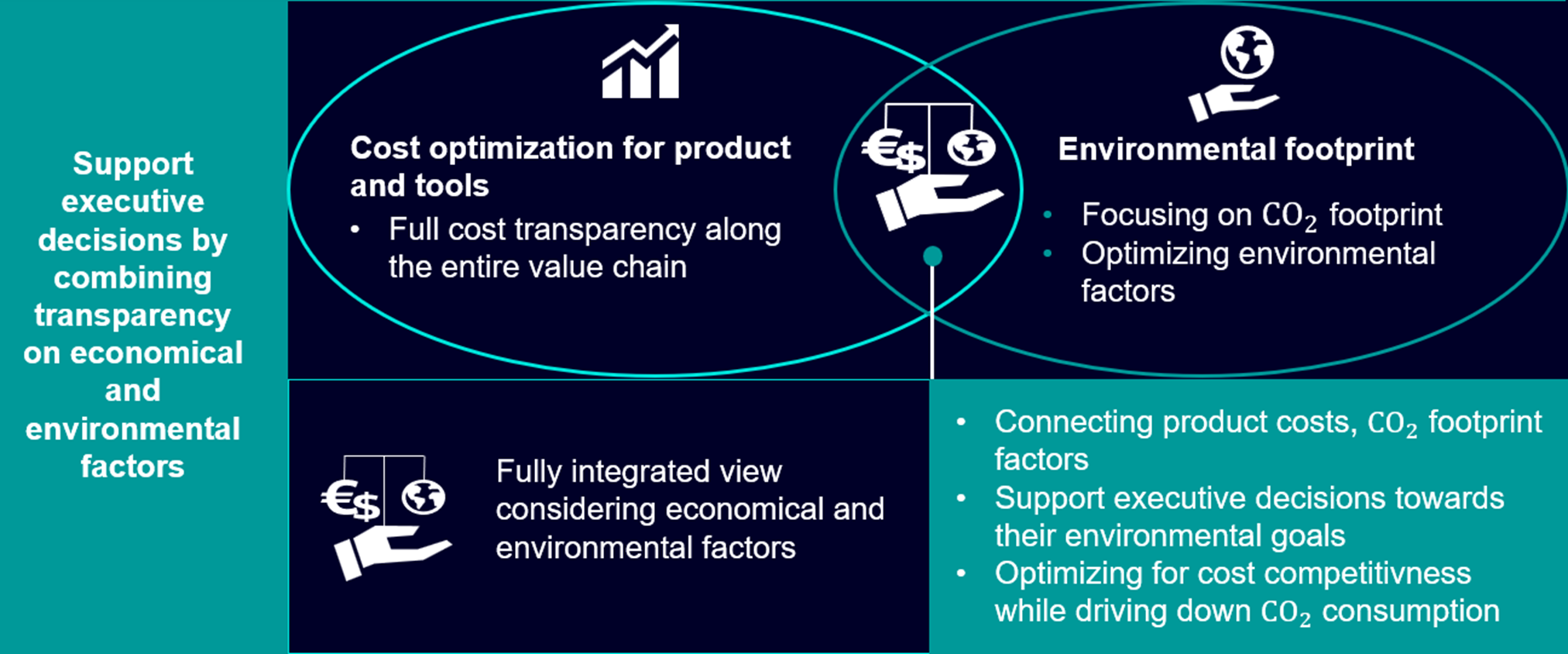

Teamcenter Product Cost Management (PCM) is a powerful software solution that enables enterprises to effectively manage their product costs while simultaneously reducing their carbon footprint. By integrating carbon footprint calculations with cost management. Teamcenter PCM empowers companies to make informed decisions that balance sustainability goals with financial performance.

Enhancing Value with Teamcenter Product Cost Management

Teamcenter Product Cost Management supports the cost and value engineering approach at an early stage of the development process by providing cost transparency for products and tools.

This enables a quantifiable decision base for cost-optimized products.

With the integrated product profitability calculation in Teamcenter, companies can secure product investments by predicting future product costs and prices over the entire product lifecycle.

The software provides a digital twin of product and tool costs, allowing for accurate representation of planned and simulated costs. Teamcenter also increases the speed and accuracy of request for quote responses, helping companies win more business. By using Teamcenter as the technological core of their cost and value engineering ecosystem, Siemens AG has supported over 1,000 projects and demonstrated impressive business impact in practice.

Optimization using value and cost engineering across commodities

Siemens offers a comprehensive solution for cost, risk, and sustainability management through the process integration of Teamcenter Product Cost Management and Supplyframe. This powerful combination enables companies to tackle cost management strategies across all commodities within product development. Teamcenter Product Cost Management provides a centralized platform for managing cost calculations, enabling standardized costing methods, fact-based calculation models, and transparency into cost drivers. This allows companies to optimize product costs, maximize margins, and achieve target costs throughout the product lifecycle. By combining Supplyframe with Teamcenter Product Cost Management, companies can access real-time market intelligence, risk assessments, and sustainability data for various commodities. This information empowers product development teams to make informed decisions regarding material selection, supplier sourcing, and design optimization. The integrated solution supports cost reduction strategies such as:

- Identifying alternative materials or components that offer cost savings without compromising quality or performance

- Optimizing product designs to reduce material usage, minimize waste, and improve manufacturability

- Leveraging supplier intelligence to negotiate better prices and mitigate supply chain risks

- Incorporating sustainability metrics into cost calculations to balance environmental impact with financial performance

By covering all commodities within product development, Siemens' solutions enables a holistic approach to cost management that considers the entire product lifecycle. This empowers companies to make strategic decisions that optimize costs, mitigate risks, and drive sustainability across their product portfolios.

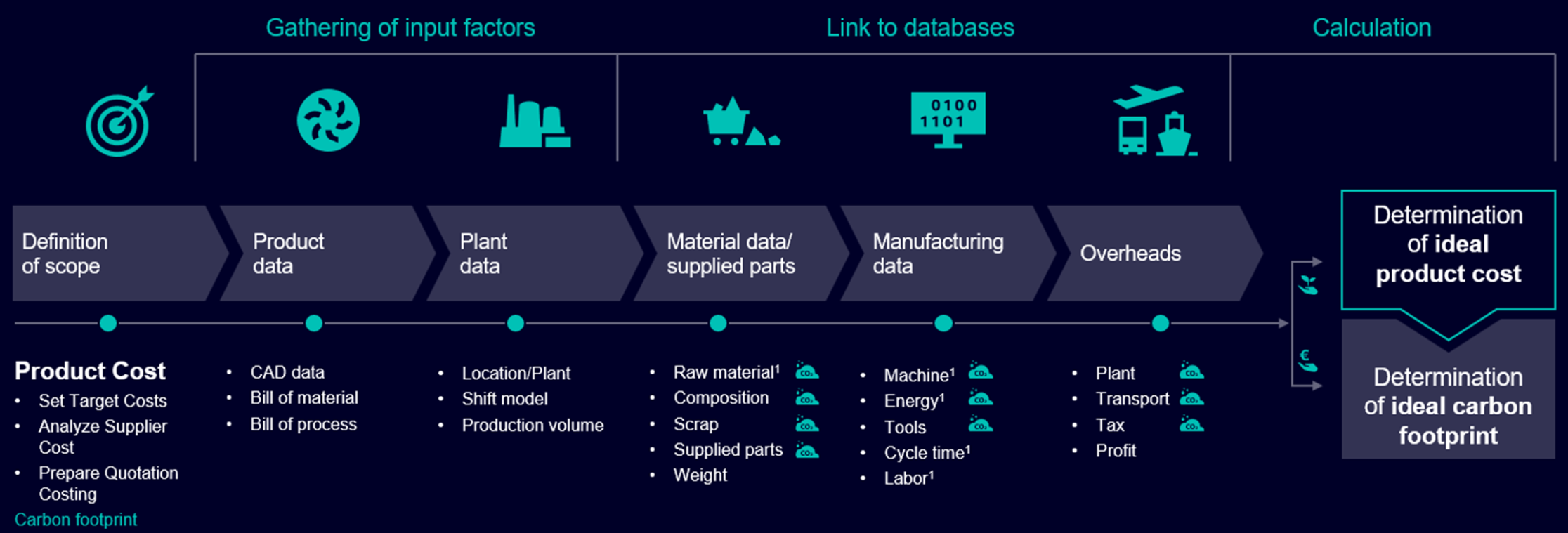

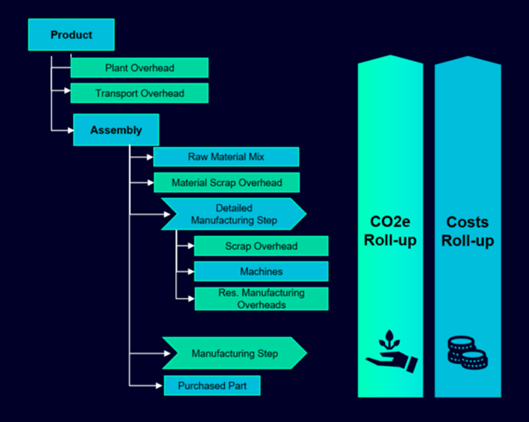

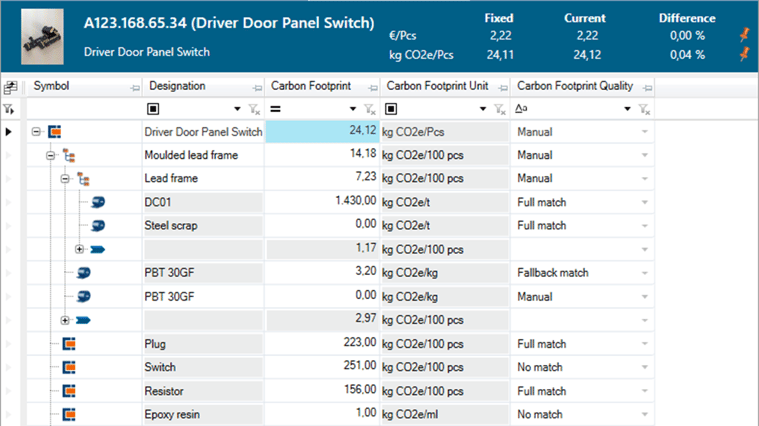

Granular Carbon Footprint Analysis

Teamcenter PCM allows companies to perform detailed carbon footprint calculations at a granular level, analyzing emissions from raw material extraction, manufacturing processes, and transportation (cradle-to-gate). This enables enterprises to:

- Identify and target the most significant carbon footprint drivers

- Support eco-design strategies by integrating ecological aspects into product planning, development, and design processes from the early stages

- Ensure a significant portion of a product's environmental impact is determined during the design phase

By understanding specific emission sources, companies can make targeted efforts to reduce their carbon footprint effectively.

Simulation and Optimization

Teamcenter PCM offers powerful simulation capabilities that allow companies to explore various scenarios for reducing carbon emissions. These simulations enable enterprises to evaluate the impact of strategies such as:

- Material substitution

- Weight reduction

- Increased recycling ratios

- Optimized manufacturing processes

By leveraging these simulations, companies can identify the most effective approaches to minimize their carbon footprint while maintaining cost efficiency. Teamcenter PCM also facilitates cross-functional collaboration between departments, ensuring all stakeholders are aligned in their efforts to reduce carbon emissions and maintain profitability.

Transparency and Reporting

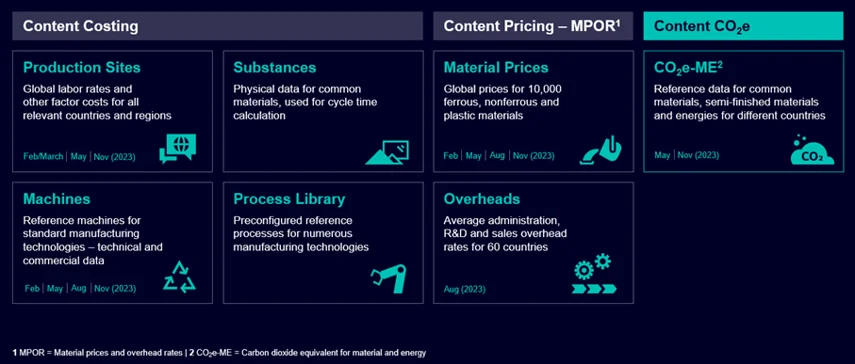

Teamcenter PCM enhances transparency by providing detailed reports on carbon emissions and costs, which are essential for internal decision-making and meeting regulatory requirements related to carbon reporting and taxation. The software can also factor in carbon taxation, helping companies understand and manage the financial implications of their carbon footprint. Furthermore, Teamcenter PCM is continuously updated with new data and capabilities, ensuring that companies have access to the latest information and tools for managing their carbon footprint. This includes updated reference data for materials, energy prices, and manufacturing processes, which are critical for accurate and timely carbon footprint calculations.

Cost Management Strategies with Teamcenter Product Cost Management

Teamcenter Product Cost Management provides powerful tools for implementing cost management and savings strategies.

One example is the use of the software's product costing feature to optimize product designs for cost efficiency. By leveraging the enterprise-wide platform for managing calculations and standardized costing methods, companies can accurately model and analyze product costs early in the development process. This enables engineers to explore alternative materials, manufacturing processes, and design choices to reduce costs without compromising quality or performance. For instance, a company could use Teamcenter PCM to compare the cost impact of using different grades of steel for a component, considering factors such as raw material prices, processing costs, and supplier quotes. The software's ability to provide transparency into cost drivers helps identify areas where cost savings can be achieved through design optimization. Another cost-saving strategy supported by Teamcenter PCM is the use of its tool costing feature to optimize manufacturing tooling investments. By accurately modeling and simulating tool costs, companies can make informed decisions about tool design, materials, and manufacturing processes to minimize tooling expenses. This can involve exploring alternative tool designs, optimizing tool life, and negotiating better prices with tool suppliers based on the detailed cost data provided by Teamcenter PCM

Furthermore, Teamcenter's integration capabilities allow companies to connect cost data with other enterprise systems, such as ERP and PLM, for a holistic view of product profitability.

This enables cross-functional collaboration between engineering, manufacturing, procurement, and finance teams to identify and implement cost-saving initiatives across the entire product lifecycle. By leveraging Teamcenter Product Cost Management's robust cost modeling, analysis, and optimization capabilities, companies can effectively implement cost management and savings strategies that drive profitability and competitiveness in the market.

Siemens AG Case Study

Siemens AG has successfully leveraged Teamcenter PCM to balance costs and carbon footprint across its product portfolio. By integrating carbon footprint calculations with cost management, Siemens AG has made strategic decisions that optimize both environmental and financial performance. The company plans to:

- Scale the use of Teamcenter PCM to cover more business units

- Leverage the software's capabilities to achieve its sustainability goals

- Continue analyzing the trade-off between carbon footprint, profit margin, and customer value to make informed decisions based on long-term risk mitigation potential and available resources

Link: https://resources.sw.siemens.com/en-US/case-study-siemensag

Implementing Cost-Effective Value Engineering

In summary, implementing cost and value engineering using Siemens solutions like Teamcenter Product Cost Management offers significant benefits for enterprises. By leveraging these powerful tools, companies can optimize costs, enhance profitability, and drive sustainability across their product portfolios. Siemens AG itself has successfully demonstrated the impact of using Teamcenter as the core of its cost and value engineering ecosystem. Siemens plans to significantly increase cost and value engineering coverage in the coming years, with Teamcenter playing a key role in this expansion. Other companies can realize similar benefits by adopting Siemens solutions for cost and value engineering. These tools enable detailed cost analysis, accurate cost modeling, data-driven design decisions, and enhanced supply chain relationships. By aligning costs with strategy and optimizing product costs across the lifecycle, enterprises can gain a competitive edge in their respective markets. Moreover, Siemens solutions support sustainability goals by allowing companies to calculate carbon footprints, model emission reduction scenarios, and make eco-friendly design choices. This helps enterprises balance environmental responsibility with financial performance, ensuring long-term success in an increasingly sustainability-focused business landscape.

Tags:

Product Cost Management, Teamcenter Product Cost Management, Teamcenter, Sustainability, Carbon Footprint

July 18, 2024